Pulse Industries to Build First Mass-Production Facility for Industrial Linear Accelerators which can be applied to water treatment systems capable of destroying ‘forever’ chemicals.

MARIANNA, FL – Pulse Industries will establish a 278,000-square-foot advanced manufacturing facility at the Marianna Airport Industrial Park, marking a transformative milestone in the mass production of linear accelerator systems. This initiative will create hundreds of skilled jobs and profoundly expand the accessibility of electron beam technology for diverse global industries.

Revolutionizing Industrial Linear Accelerator Manufacturing

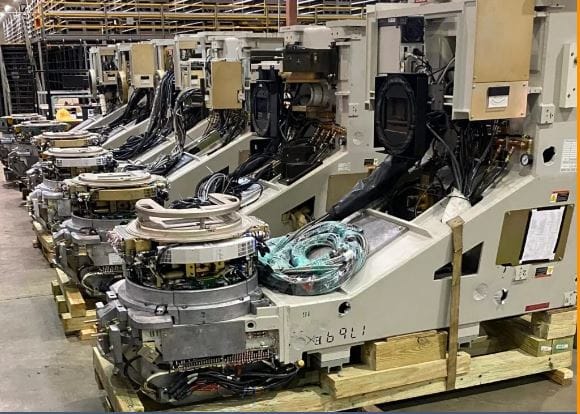

This new facility is the first fully integrated operation designed for the development, rapid mass production, and deployment of industrial linear accelerators, representing a groundbreaking shift from small-batch methods to commercial-scale manufacturing. Similar to the Ford Model T’s revolutionary approach, Pulse’s transition to mass production will dramatically increase the availability of electron beam technology while enhancing product standardization, efficiency, consistency, and economies of scale.

Leadership Vision

“This facility is unprecedented in both scope and ambition,” said Dr. Eric Burgett, President and CTO of Pulse Industries and a pioneer in nuclear engineering. “By establishing the world’s first vertically integrated mass production capability for industrial linear accelerators, we are not just creating a factory—we are creating a new industrial category. This technology will become accessible at a scale once considered impossible, while driving the creation of hundreds of advanced manufacturing jobs and strengthening America’s position in this critical industry.”

Advanced Manufacturing and Technology Demonstration

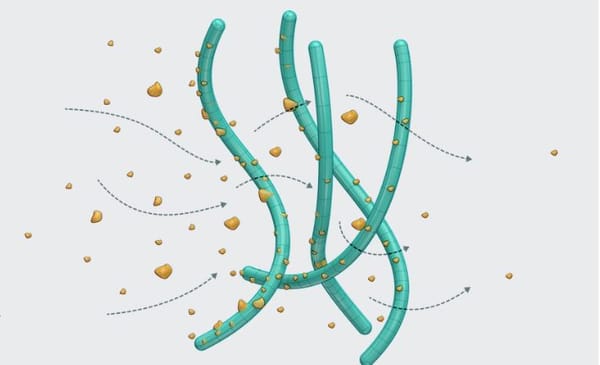

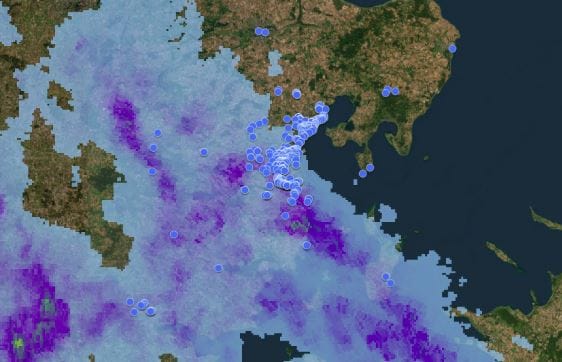

The facility will feature advanced automation and precision manufacturing systems for the design and mass production of electron beam systems deployed across multiple industries. It will include demonstration and certification capabilities—such as treatment cells for medical device sterilization, food safety applications, a 6,000-barrel-per-day electron cold cracking system for petroleum upgrading, and water treatment systems capable of destroying ‘forever’ chemicals. These on-site resources will ensure rapid certification and deployment of mass-produced systems while demonstrating their environmental and sustainability advantages over traditional chemical treatment processes.

Economic Impact and Regional Development

“This facility makes Jackson County the global epicenter for linear accelerator innovation and mass production,” said Darwin Gilmore, Director of the Jackson County Economic Development Office. “Its scale will establish our region as a hub for advanced manufacturing while creating sustainable, high- paying jobs in one of the world’s most innovative industries.”

Workforce Development and Training

The comprehensive workforce development program will establish new career pathways in advanced manufacturing, nuclear engineering, and sustainable technology operations. Employees will gain specialized skills in linear accelerator design, engineering, assembly, precision manufacturing, and system integration, supporting the rise of a skilled workforce in this emerging industry. Sustainable Operations

Powered in part by behind-the-meter solar energy, the facility will align large-scale manufacturing with environmental responsibility. Initial operations will commence in mid-2025, ushering in a new era of industrial technology manufacturing.

Mission Statement

Through advanced technology, mass production, and strategic joint ventures, Pulse is on a mission to transform how humanity powers, heals, and preserves civilization. Pulse Industries was a winner of the Earth 05 Co-creation prize in 2025. See Company Profile.

Comments

OceanWell Taps Deep Ocean to Redefine Sustainable Desalination

Water scarcity is rapidly becoming one of the most pressing global challenges, driven by climate change, population growth, and declining freshwater reserves. While desalination has long been seen as part of the solution, conventional systems remain energy-intensive, land-heavy, and environmentally controversial. OceanWell is advancing a new approach that rethinks how

Revolutionizing Water Management: How Technology is Tackling Water Waste in Buildings.

Shayp client ING went live in 2022 and has already saved over 3 million litres per year. In a couple of months, they were able to avoid 473 kg of carbon emissions by just monitoring their water and taking action efficiently.

New Ecosystem Resource Directory Launched to Support Water Technology Companies Worldwide

A new Ecosystem Resource Directory is being developed to support water technology companies working to scale breakthrough innovations and proven solutions across the global water sector. The initiative aims to create a comprehensive, practical inventory of resources available to companies navigating the complex journey from innovation to market scale. By

Pilot success at Atlantic County Utilities Authority (ACUA) paves way for full-scale deployment of PolyGone Systems micro-plastic removal technology

Atlantic City, NJ — November 8, 2025 — A year after the grand unveiling of the micro-plastic removal pilot at ACUA’s wastewater treatment facility, the partnership between PolyGone Systems and ACUA is now transitioning into a full-scale implementation phase — marking a significant milestone in the fight against micro-plastic pollution in treated

Dryp Unveils “Lens” Platform to Unite Utility Data Streams. Integration of diverse data streams from utilities into a unified interface can result in 90% reduction in data analysis time.

Copenhagen, Denmark — November 8, 2025 — Danish cleantech firm Dryp A/S today announced the launch of “Lens”, a new hydraulic-data visualisation and analytics platform designed to integrate diverse data streams from utilities into a unified interface. Utilities amass vast volumes of information — from SCADA pump readings and GIS maps, to