Pilot success at Atlantic County Utilities Authority (ACUA) paves way for full-scale deployment of PolyGone Systems micro-plastic removal technology

Atlantic City, NJ — November 8, 2025 — A year after the grand unveiling of the micro-plastic removal pilot at ACUA’s wastewater treatment facility, the partnership between PolyGone Systems and ACUA is now transitioning into a full-scale implementation phase — marking a significant milestone in the fight against micro-plastic pollution in treated effluent waters.

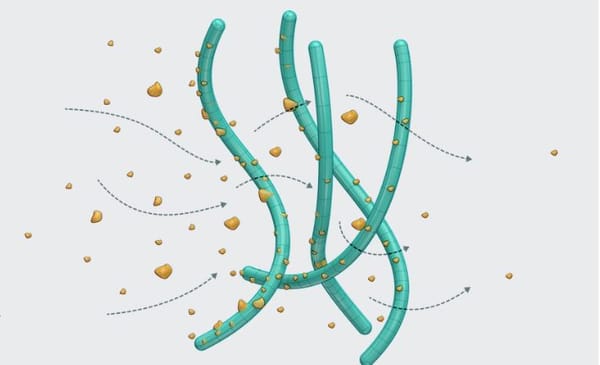

Back in September 2024, PolyGone launched its first industrial-scale pilot of its so-called “Artificial Root Filter” at ACUA’s facility (which treats approximately 40 million gallons of wastewater per day). The system, installed in the effluent equalization basin, is designed to intercept hydrophobic and buoyant micro-plastic particles that would otherwise bypass conventional wastewater treatment.

According to PolyGone’s website, the pilot has now processed and removed more than 520 million micro-plastic particles, over 720 filter trays have been deployed, and the site serviced more than 220,000 households — figures that underline the scale and effectiveness of the technology in its first year.

Key Outcomes

- The pilot consistently exceeded performance targets for micro-plastic removal, with lab analyses showing a marked reduction in micro-plastic load in the treated effluent stream. (Internal data from PolyGone and ACUA.)

- The educational pavilion sited alongside the filtration system has welcomed thousands of students and community visitors, helping raise awareness of micro-plastic threats and filtration solutions.

- The partnership forged under funding from the NOAA Sea Grant Marine Debris Challenge Competition and the New Jersey CSIT Clean Tech Demonstration Grant has retained momentum into 2025, with discussions underway to scale the system to other wastewater-treatment facilities across the U.S.

Next Steps & Outlook

With the pilot phase deemed successful, ACUA and PolyGone are now preparing for Phase 2, which will convert the pilot into a full-scale operational system, optimized for continuous use rather than demonstration. The roll-out will include:

- Installation of additional filter arrays to cover the full plant effluent flow rather than a subset.

- Formal integration into ACUA’s routine operations and maintenance schedule (filters cleaned weekly, replaced semi-annually under the pilot)

- Deployment of collected micro-plastics into up-cycling or resource-recovery pathways, turning what was a waste stream into a feedstock.

- Expansion of the technology to other municipalities, informed by the ACUA pilot results and operational lessons.

ACUA President Matthew DeNafo remarked: “This pilot has proven that micro-plastic removal is not only feasible at municipal scale but can be operationalized. We are proud to lead the way.”

PolyGone co-founder Yidian Liu added: “We’ve moved from demonstration to deployment. The next few months will focus on system refinement and replication so that we can bring this solution to many more treatment plants.”

Implications for Industry & Policy

- Municipal wastewater utilities: The ACUA example offers a blueprint for how treatment plants can cost-effectively add micro-plastic removal atop existing processes.

- Regulators & policymakers: With mounting evidence that conventional treatment does not capture many micro-plastics, the pilot’s success provides a real-world data point for potential new standards or incentives.

- Cleantech & circular-economy sectors: The integration of micro-plastic capture with up-cycling creates a novel value chain, turning a pollutant into a feedstock.

- Research & education: The project’s educational pavilion underscores the importance of linking infrastructure deployment with public engagement — especially when dealing with emerging contaminants like micro-plastics.

Quotes of Note

“We’ve removed over half a billion micro-plastic pieces in under a year, from a plant serving 220,000 residents — the data speaks for itself.” — Yidian Liu, PolyGone Systems

“Our facility serves 14 municipalities and processes 40 million gallons per day. If this system works here, it can work anywhere.” — Matthew DeNafo, ACUA

What to Watch in 2025

- The formal commencement of full-scale operations at ACUA and performance metrics over the next 6-12 months.

- The announcement of partner utilities adopting the technology; whether PolyGone signs contracts beyond New Jersey.

- Policy developments at state or federal level referencing micro-plastic removal from wastewater effluent.

- The economic model: cost per ton of micro-plastics removed, capital/operating costs, and cost-benefit versus environmental/health outcomes.

Conclusion

One year in, the ACUA-PolyGone pilot has moved the needle — from concept to scalable action. With robust removal numbers, an operational plan underway and replication on the horizon, this initiative could mark a turning point in the management of micro-plastic pollution in wastewater. If the next phase maintains performance, regulators, utilities and investors may take note — and the model could scale widely. See Company Profile.

Comments

OceanWell Taps Deep Ocean to Redefine Sustainable Desalination

Water scarcity is rapidly becoming one of the most pressing global challenges, driven by climate change, population growth, and declining freshwater reserves. While desalination has long been seen as part of the solution, conventional systems remain energy-intensive, land-heavy, and environmentally controversial. OceanWell is advancing a new approach that rethinks how

Revolutionizing Water Management: How Technology is Tackling Water Waste in Buildings.

Shayp client ING went live in 2022 and has already saved over 3 million litres per year. In a couple of months, they were able to avoid 473 kg of carbon emissions by just monitoring their water and taking action efficiently.

New Ecosystem Resource Directory Launched to Support Water Technology Companies Worldwide

A new Ecosystem Resource Directory is being developed to support water technology companies working to scale breakthrough innovations and proven solutions across the global water sector. The initiative aims to create a comprehensive, practical inventory of resources available to companies navigating the complex journey from innovation to market scale. By

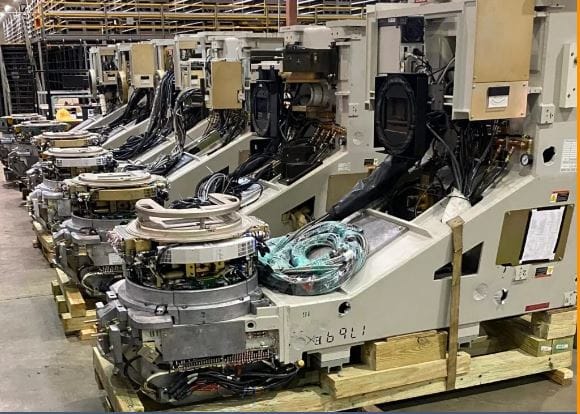

Pulse Industries to Build First Mass-Production Facility for Industrial Linear Accelerators which can be applied to water treatment systems capable of destroying ‘forever’ chemicals.

MARIANNA, FL – Pulse Industries will establish a 278,000-square-foot advanced manufacturing facility at the Marianna Airport Industrial Park, marking a transformative milestone in the mass production of linear accelerator systems. This initiative will create hundreds of skilled jobs and profoundly expand the accessibility of electron beam technology for diverse global

Dryp Unveils “Lens” Platform to Unite Utility Data Streams. Integration of diverse data streams from utilities into a unified interface can result in 90% reduction in data analysis time.

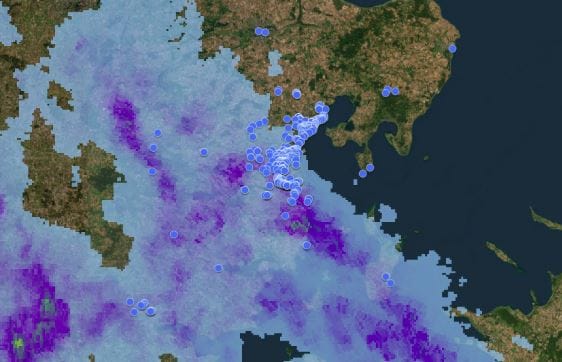

Copenhagen, Denmark — November 8, 2025 — Danish cleantech firm Dryp A/S today announced the launch of “Lens”, a new hydraulic-data visualisation and analytics platform designed to integrate diverse data streams from utilities into a unified interface. Utilities amass vast volumes of information — from SCADA pump readings and GIS maps, to